Live Room Booths Apr 13th 2011

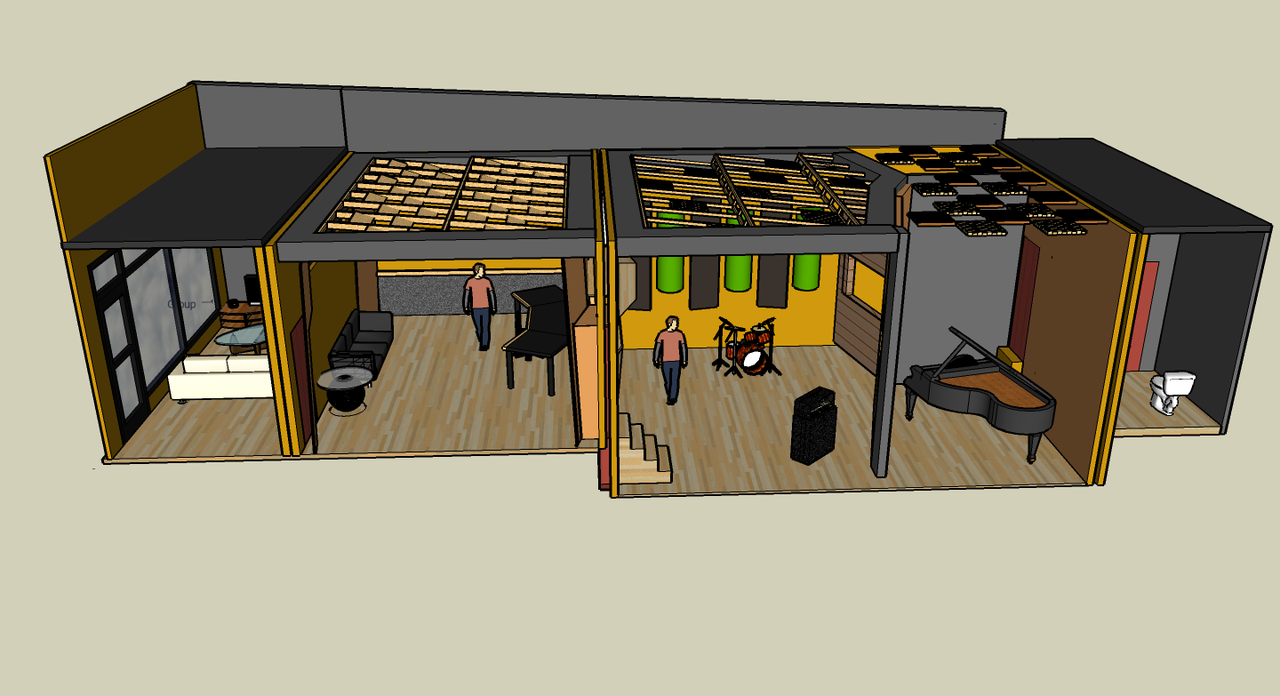

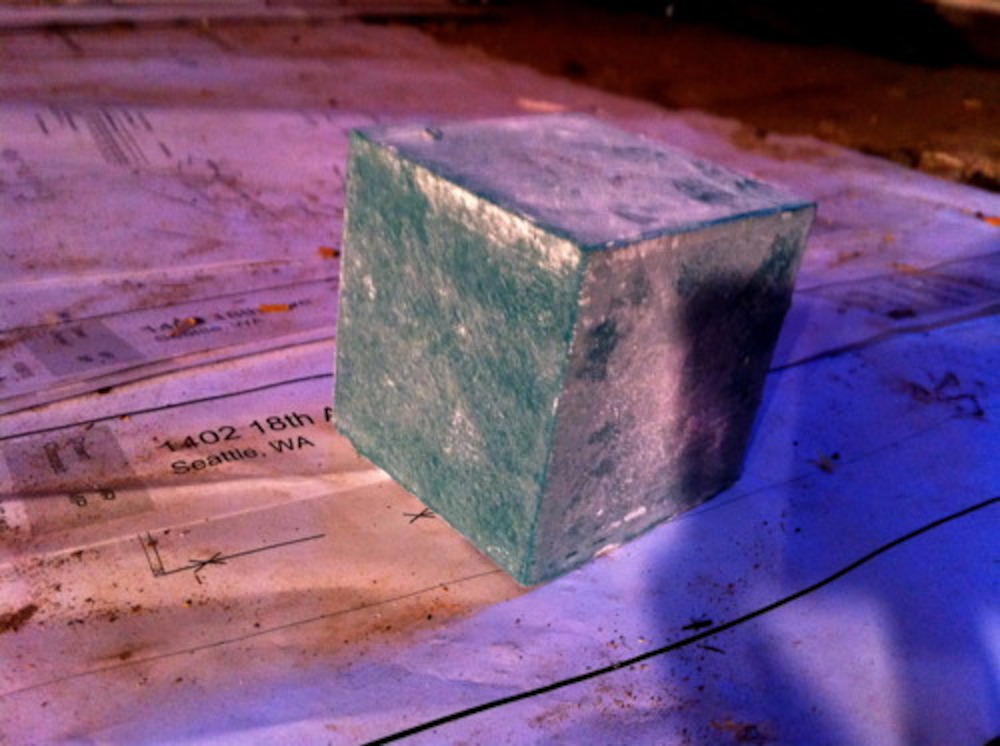

After using a chalk line to map out the shape of the booths we used 3 ½" strips of sound deadening board to act as a decoupling barrier between the studs and the walls, floor & ceiling.

Notice the two layers for the inner and outer walls.

Beginning of the framing. Planing on using french doors in this booth so we can roll a piano in and out.

Progress.

Notice the little line of sight window in the side wall.

One layer of sheet rock on the inner wall.

Starting on the floor in booth 1.

Both booths inner walls framed and sheet rocked. Outer wall frames done also.

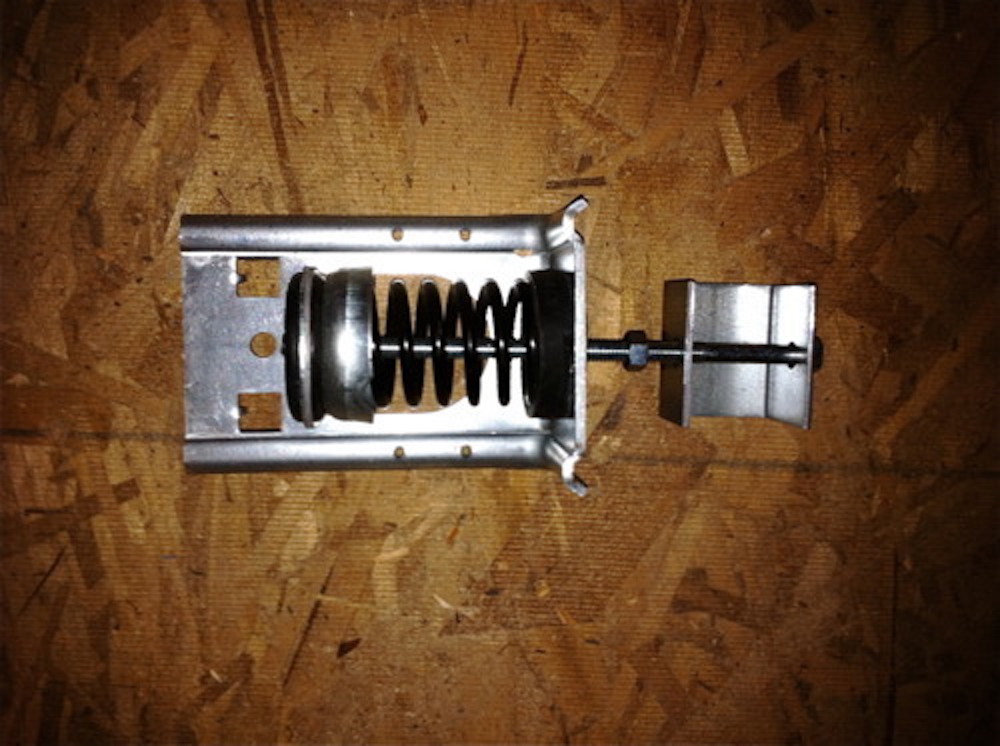

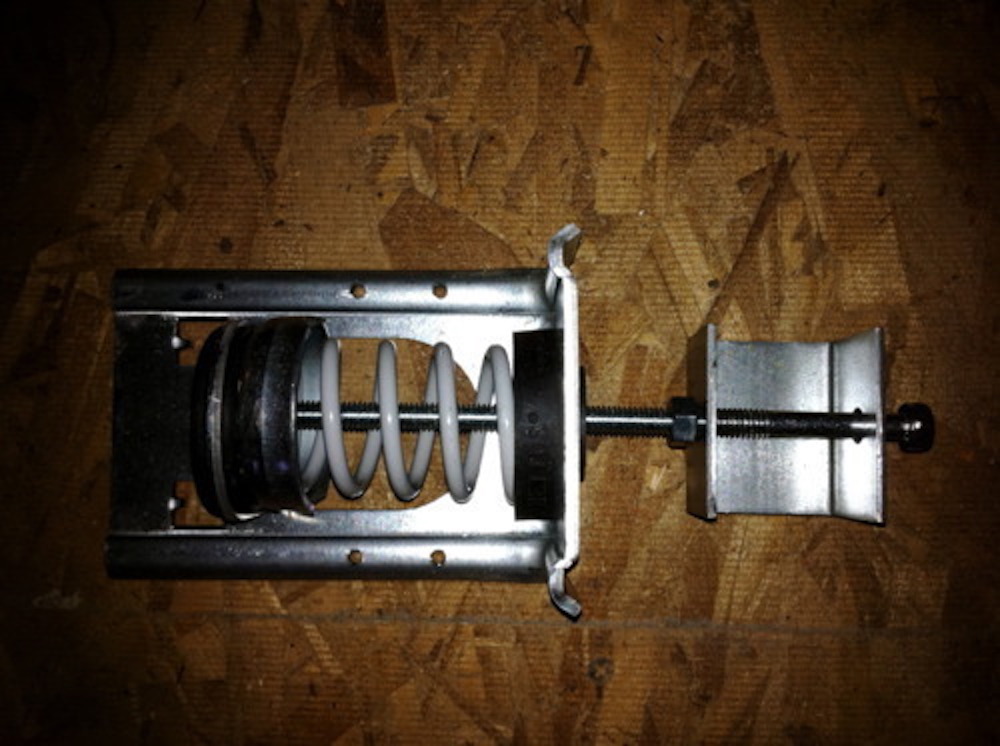

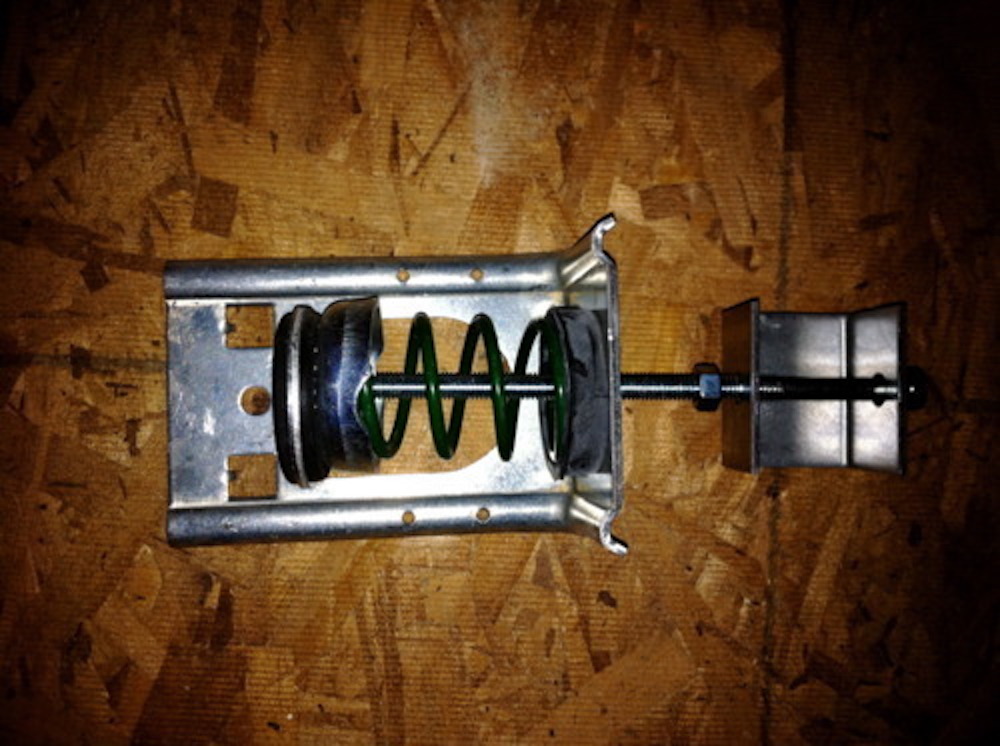

Started on the isomax clips & hat channel for the two layers of sheet rock on the outer walls.

A little mod on the hat channel to accommodate a tight corner.

The tight corner. It also reduces the amount of clips needed.

Metalwork done on the outer walls.

Just one more wall to do in booth 2.

Insulation done. Again I used R30 paperless and split it down the middle to make R15.

It’s cheaper and accommodates the extra little gap between the walls.

Wall in booth 2 insulated.

Starting on the 2 layers of sheet rock.

Notice I am placing the sheets on the foam matting. This will help decouple the walls from the floor as there is a common floor both inside and outside the booths.

Starting on the soffit in booth 1.

First layer of sheet rock done. Used up a lot of the scraps hence the patchwork quilt look.

Second layer of sheet rock done and the first pass of mud & tape.

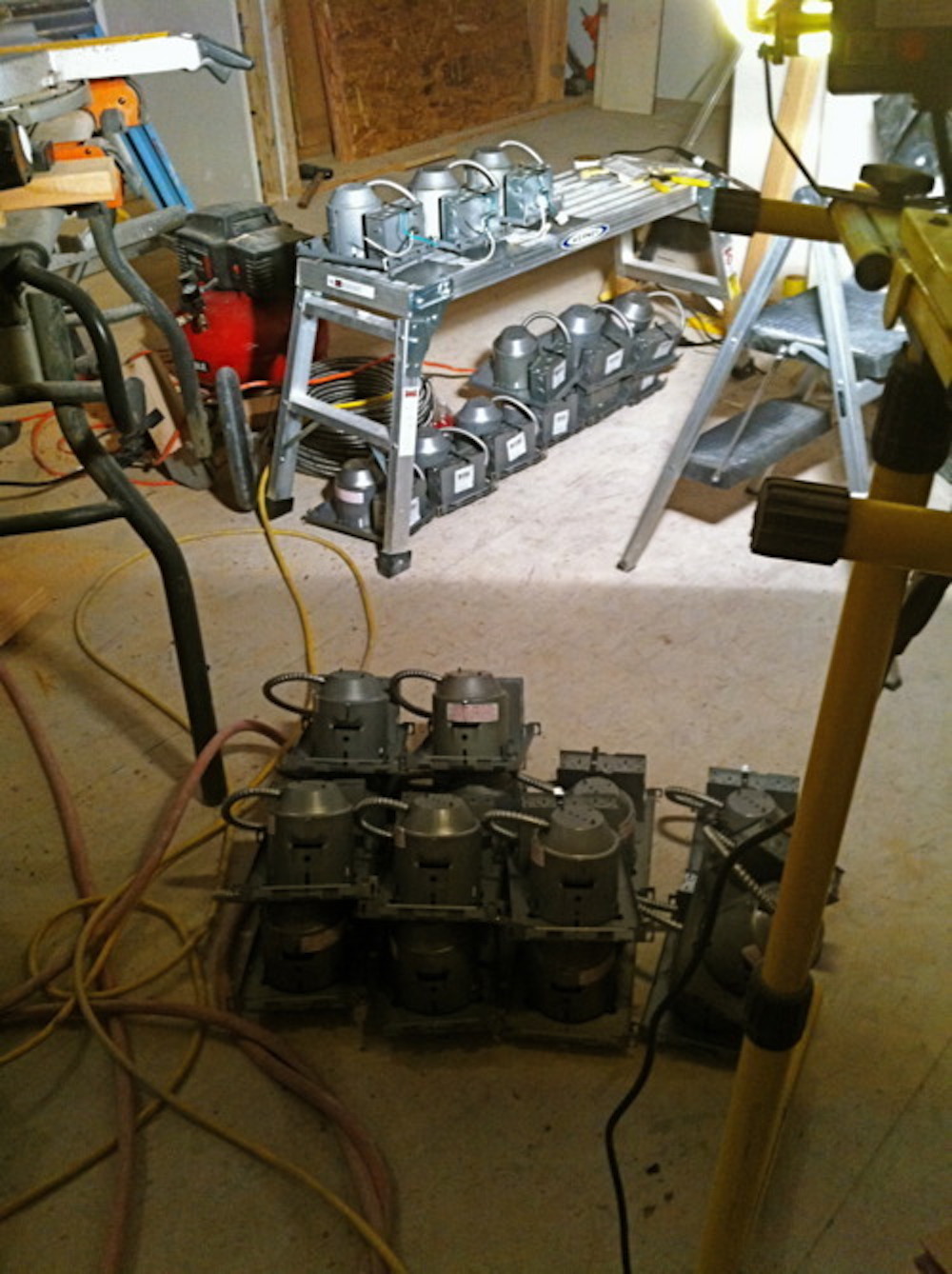

The lighting cans for the live room soffit.

Booth 1 soffit frame done.

Booth 2 soffit frame done.

Booth 2 soffit cans & lath done.

Karen came up with a much better idea for wire brushing the lath.

Sandwiched together 3 wire wheels. Mush easier and faster.

Booth 1 soffit and ceiling done.

Booth 2 soffit and ceiling done.

Tomorrow we finish the floors and doors.

Doors more or less done. Just the trim work to do.

Booth 1 floor varnished.

Booth 1 trim done.